- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Centrifugal Casting

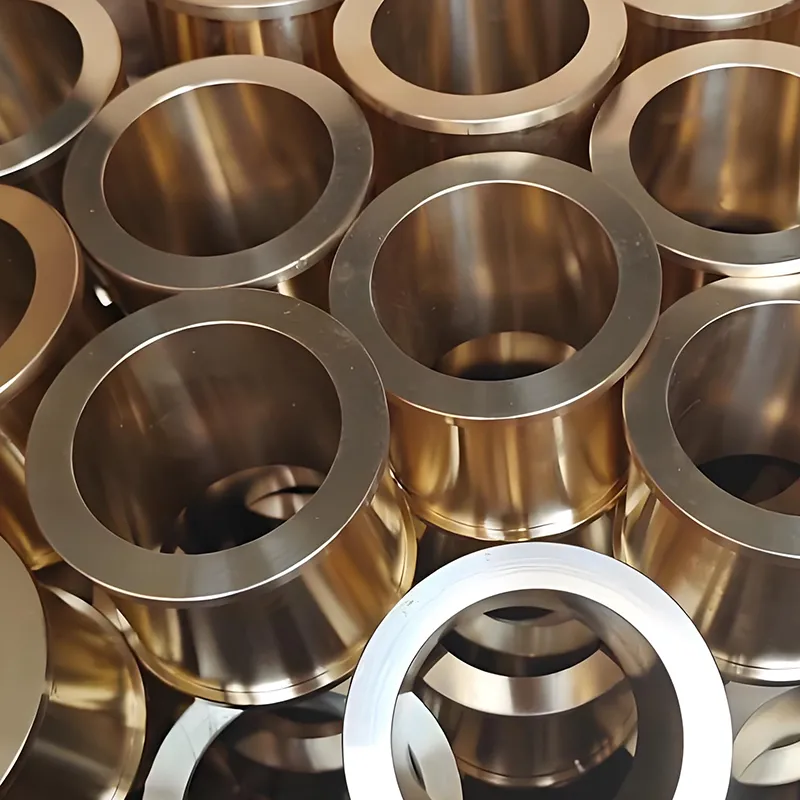

Chinese manufacturer Youlin® is committed to providing complete Centrifugal Casting service to global customers. In today's pursuit of high efficiency production and high quality, Youlin® centrifugal casting technology is becoming a brass sleeve parts manufacturing power in the field of innovation. For brass alloy parts that require high strength, high density and wear resistance, centrifugal casting technology offers an irreplaceable production solution. This casting process uses the centrifugal force generated by high-speed rotation to tightly press the molten metal against the mold wall, thereby forming a casting with outstanding mechanical properties. Especially in the manufacturing field of cylindrical sleeve parts such as brass sleeves, brass worm gears and brass nuts, centrifugal casting has demonstrated its unique technical advantages.

Send Inquiry

Brass Centrifugal Casting: An Advanced Casting Process for High-quality Sleeve Castings

01 Process Principle — the Technical Basis of Centrifugal Casting

Centrifugal casting is a casting method that uses the centrifugal force generated by rotation to form and solidify liquid metal. The core principle is to pour molten metal liquid into a high-speed rotating mold.

Under the action of centrifugal force equivalent to tens or even hundreds of times the weight of gravity, the molten metal adheres closely to the mold wall to form a hollow cylindrical shape, and solidifies and crystallizes under this pressure.

This powerful centrifugal force brings two key advantages: First, the metal feeding effect is good, and inclusions and gases are easy to be discharged; Second, the cooling direction of the casting is clear, forming directional crystallization from outside to inside.

This directional solidification characteristic significantly improves the mechanical and physical properties of the castings, making centrifugal casting particularly suitable for the production of symmetrical rotary parts such as sleeves and tubes.

02 Technical Advantages — the Outstanding Characteristics of Centrifugal Casting

● Excellent Casting Quality

The most significant advantage of centrifugal casting is its excellent casting quality. Under the strong centrifugal force, the gas and slag inclusion in the metal liquid are easy to be discharged, so that the density of the casting is high, and the defects such as pores and slag inclusion are few.

This high density directly leads to better mechanical properties, making the mechanical properties of centrifugal casting copper close to the level of forging process.

● Reduced Production Costs

Centrifugal casting process also brings significant productivity improvements and cost savings. There is no need to use a core when producing hollow castings, which greatly simplifies the production process of sleeve and tube castings.

Meanwhile, this process has almost no metal consumption in the gating system and riser system, which greatly improves the process yield and material utilization rate. For the valuable copper alloy material, the economic benefits of this material saving are particularly obvious.

● Composite Manufacturing Ability

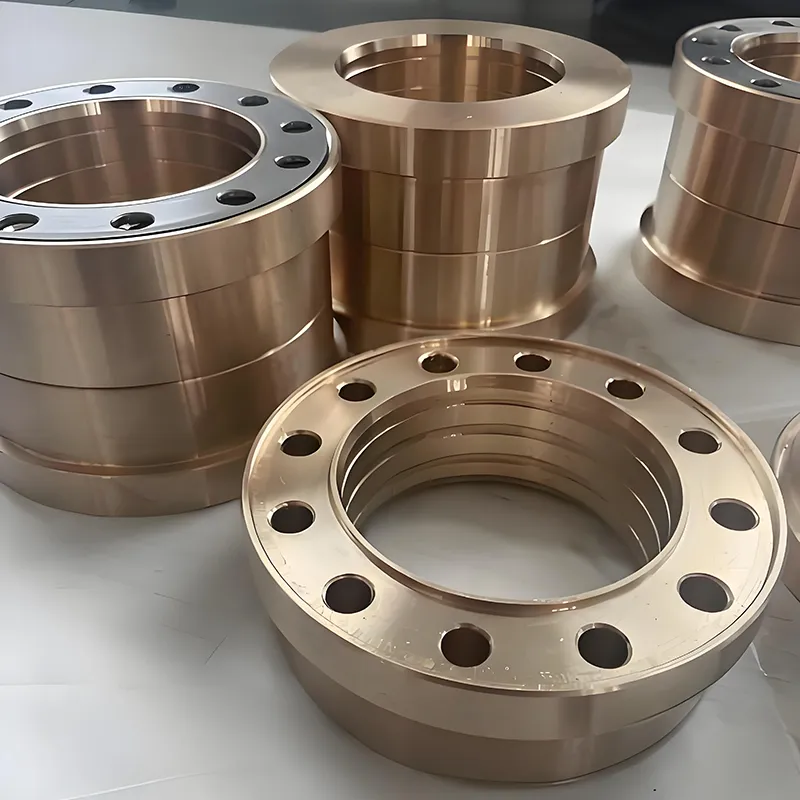

Centrifugal casting also shows unique composite manufacturing capabilities. It is convenient to make composite metal castings of tube and sleeve, such as steel-backed copper sleeve, bimetallic roll, etc.

By adopting the double liquid metal centrifugal casting composite technology, it is possible to achieve a firm composite of different metals such as steel and copper, steel and aluminum, etc. The interface is serrated, with high bonding strength and reliable quality.

This opens up a new manufacturing path for composite material parts used in special working conditions.

03 Application Limitations — the Technical Boundaries of Centrifugal Casting

Although centrifugal casting has many advantages, it is not a universal process, and understanding its limitations is essential for correct application.

Firstly, centrifugal casting has obvious limitations in the production of special-shaped castings. It is most suitable for manufacturing symmetrical rotary parts such as cylinders, sleeves and tubes, but it is difficult to handle complex-shaped castings.

Secondly, the inner surface quality of centrifugal casting is poor. The diameter of the inner hole of the casting is not accurate, and the inner surface is rough, which usually requires a large machining allowance. This makes additional machining steps necessary for application scenarios with high internal surface requirements.

Furthermore, centrifugal casting is prone to specific gravity segregation. Therefore, it is not suitable for alloys such as lead bronze that are prone to specific gravity segregation.

It should be particularly noted that it is not suitable for casting alloys which the specific gravity of impurities is greater than that of the molten metal.

04 Practical Application — the Professional Solution of Copper Centrifugal Casting

◆ Centrifugal casting of large tin bronze bushings

In practical applications, large tin bronze bushings are typical representative products of centrifugal casting. This kind of parts are widely used in the mechanical industry, with excellent wear resistance and self-lubricating characteristics, often used in the manufacture of bushing, bearing, gear and other wear-resistant parts.

In practical applications, large tin bronze bushings are typical representative products of centrifugal casting. This kind of parts are widely used in the mechanical industry, with excellent wear resistance and self-lubricating characteristics, often used in the manufacture of bushing, bearing, gear and other wear-resistant parts.

ZCuSn10Pb1 tin bronze, for example, the tensile strength of centrifugal casting condition of up to 330 MPA, yield strength of 170 MPA, the elongation is 4%, Brinel hardness can reach 785 HBS.

These data are significantly higher than the same materials of sand casting, which fully reflects the advantages of centrifugal casting in improving mechanical properties.

◆ Technical Challenges and Countermeasures

In centrifugal casting process of tin bronze bushings, the main challenges in production are reverse segregation and shrinkage. Tin bronze has anti-segregation characteristics, and its crystallization temperature range is wide, so it is easy to produce shrinkage and porosity defects.

To solve this problem, the serious shrinkage caused by bidirectional solidification was successfully solved by adding Ni alloy and adopting metal spray cooling measures.

This innovative technological measure ensures the quality stability of large tin bronze bushings during the centrifugal casting process, making their strength and pressure resistance meet the requirements of harsh working conditions.

◆ Diversified Product Range

Centrifugal casting technology can produce a variety of copper alloy products. Common grades include: QSn4-3, QSn4.4-2.5, QSn7-0.2, ZQSn10-1, ZQSn5-2-5, ZQSN6-6-3, etc.

The copper sleeves, copper tiles, copper sliding plates, copper worm gears and other products produced from these materials are widely used in the electrical and electronic, mechanical manufacturing, transportation vehicle and other industries, demonstrating excellent technical and economic performance.

With the continuous improvement of the quality requirements of parts in the manufacturing industry, the position of centrifugal casting technology in the manufacture of copper alloy parts will be more consolidated. This process is not only suitable for the production of large tin bronze copper sleeve, but also shows great potential in the field of bimetallic composite castings.

In the future, with the continuous maturation of centrifugal casting composite technology, we will be able to see more high-performance and long-life copper alloy castings serving various industrial fields.

Whatever you need is copper set of regular or special alloy casting, centrifugal casting technology can provide you with excellent performance, cost optimization solution.